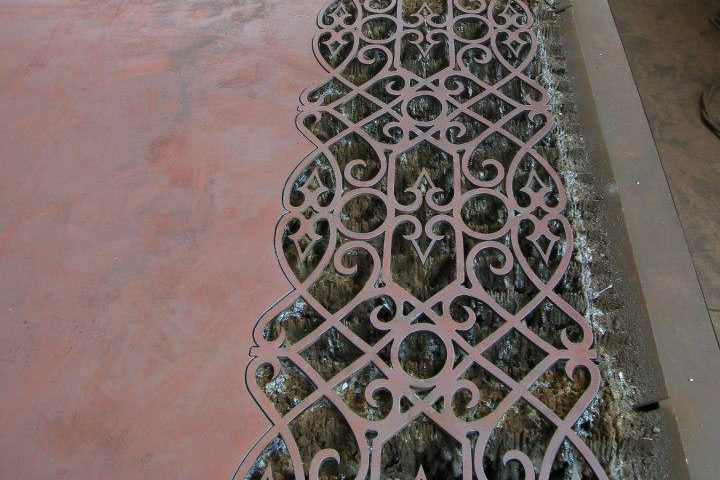

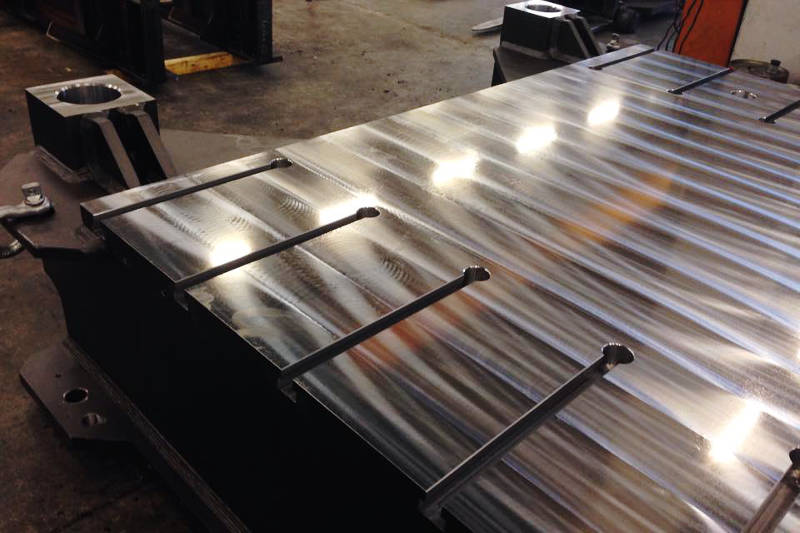

An equipped workshop allows us to offer medium-heavy carpentry works, paying the maximum attention to the production flow controls and to the quality standards necessary for a more and more demanding market.

We have a 3000 sq.m indoor area plus 2000 sq.m outdoor area, and we have also obtained the EN ISO 9001-2015, EN 15085 certification and Industry 4.0